One of the oldest methods of recovering gold from stream gravel is the sluice box that has been around for thousands of years. All a sluice box is literally a box that is open on both ends and does not have a top. Other than the gold pan the sluice box and its variations are still used today for the recovery of gold in both small-scale and large-scale placer mining.

|

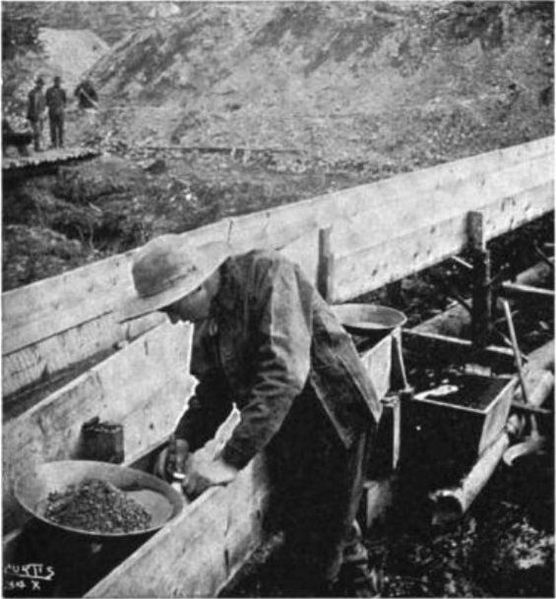

| Removing gold from a sluice box |

All sluice boxes are lined with riffles designed for the recovery of gold that usually take two parts. On the bottom of the sleuth box is covered with some sort of fabric usually indoor/outdoor carpeting, or another effect of gold trap is the backside of a strip of conveyor belt. The riffles in a sluice box represent obstructions in a flowing stream of water that mimic naturally occurring obstructions found in a streambed.

Sluice boxes come in all sizes ranging from a 3 foot aluminum version that is portable enough to be handcarried to the stream where you are going to work. The other extreme is found at work in many commercial gold mining projects all over the world. Most of these sluice boxes are built from wood where they are going to be used, and it is unusual for one of these large sluice boxes to be several hundred feet long and more than 10 feet across with sides are least 4 feet high.

|

| Gold miners using a variation of a sluice box in Nome, Alaska |

During the late 1960s I happened to witness how one of these large sized commercial sluice boxes was cleaned of gold from a season's worth of operation. This sluice box was in the Yukon Territory of Canada, and had been in operation for the entire season, and was closed down when the weather started getting cold. As a rough idea of how large this thing was it appeared to be about 125 feet long, 12 feet wide and had sideboards that extended up to 6 feet. The gravel was fed into the upper end of the sluice box by a front end loader that was probably dropping several cubic yards of gravel at a time into upper end of the sluice box.

Water to operate the sluice box came from a dam about 1/2 mile up the river and probably 20 feet higher than the sluice box. This water was channeled down into the sluice box with enough force so it was able to wash away the gravel as it was being added. The riffles at the bottom of this sluice box or cast-iron grates from storm drains. It looked like a miner had half the grates from the storm sewers in Toronto

|

| Miners operating a sluice box during the California Goldrush |

There was another front end loader working at the tail end of the sluice box to remove the gravel that had worked its way down through the length of the box, and poured out of the lower end.

When the operation shutdown in the fall they started removing these grates from the top end of the sluice box, and work their way down. There was enough gold caught under the grates at the upper end that are just about made your eyes pop out. The miners were removing it from the sluice box with shovels and pouring the gold into plastic buckets.

Thank you for the insight. We started using a sluice to prospect for gold and gemstones near Dahlonega, Georgia. We also blog about it!

ReplyDeletehttp://www.americangeode.com